Main characteristics

1. 202 digital MEMS microphones, algorithm upgrade, more accurate listening and positioning recognition

2. 13 million high-definition imaging, fully displayed in the nanometer range

3 LeakQ ™ Mode: Real time display of leakage rate and estimation of leakage cost

4. PDQ mode ™: Determine the type of partial discharge, estimate the probability of partial discharge, and present the PRPD map in real-time

4. Report function: Integrated visual and text tagging and annotation functions, one click report generation on the device side

5. The body weight is only 1.2kg, making one handed inspection effortless

6. IP54 dustproof and waterproof, 2m anti fall

7. 7-inch LCD touch screen, comfortable observation, easy operation

8. Supports WIFI/Bluetooth/USB, efficient and stable data transmission

- Product Detail

- Product Overview

- Configuration

Fluke ii1020C Acoustic Imager

Expert in gas leakage, partial discharge, and airtightness testing.

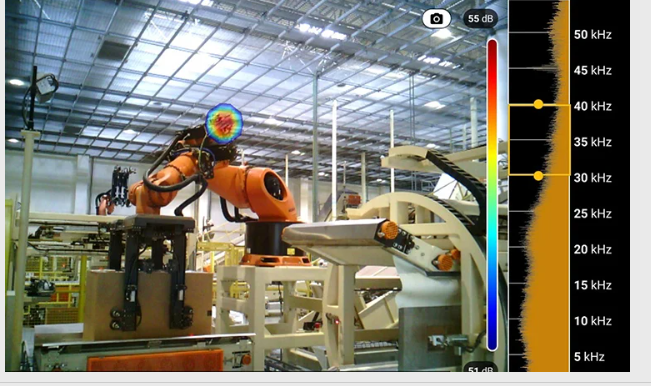

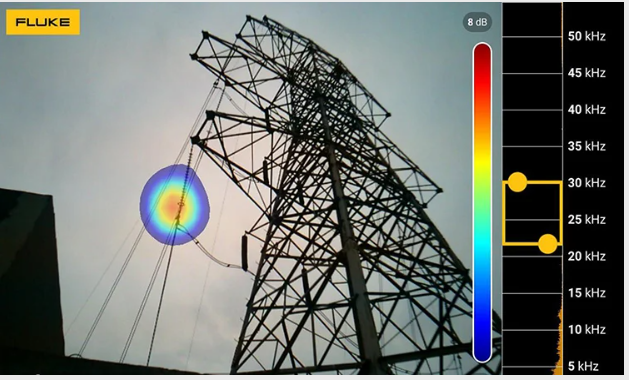

SoundSight ™ The technology overlays ultrasound images onto visible light images, helping engineers locate problem points in real-time and quickly. Fluke ii1020C is equipped with two detection modes: LeakQ ™ Mode and PDQ mode ™。 LeakQ ™ In the PDQ mode, the device can display the size of the leakage in real time and estimate the leakage cost ™ Implementing partial discharge pattern/type recognition and probability evaluation through integrated machine learning models. After the detection is completed, the device can generate a report with one click, saving time and effort.

Gas leakage detection

1. Accurate detection: 202 digital MEMS microphones combined with upgraded algorithms, -26dBFS high-sensitivity imaging, quickly capturing leakage points of compressed air, vacuum negative pressure systems, and pneumatic equipment, fearless of noisy industrial environments.

2. Quick positioning: SoundSight ™ The technology converts the sound waves generated by leaks into sound images, which are overlaid on visible light images. 13 million high-definition pixels combined with 3x digital zoom, presenting problem points clearly on a 7-inch LCD screen.

3. Energy saving and efficiency increasing: LeakQ ™ In this mode, real-time monitoring of leakage rate and quantitative loss assessment can help enterprises reduce energy waste and save production costs. One click report generation on the device side to optimize workflow.

4. Ensuring safety: Detecting hazardous gas leaks at a safe distance, taking proactive preventive measures, and ensuring safe and reliable production.

Application scenarios:

Leakage of air/carbon dioxide pipeline

Refrigerant leakage detection

Tank airtightness testing

Air pressure driven joint leakage

Transport vehicle connection point

Leakage in the air compressor room

Production line gas leakage

Gas leakage in the distribution chamber

Key areas requiring partial discharge detection:

insulator

transformer

High voltage wire

switch gear

lightning arrester

a bus or bus bar

COIL

Circuit breaker

capacitor

Airtightness testing:

Accurate detection: Equipped with 202 digital MEMS microphones and upgraded algorithms, -26dBFS high-sensitivity imaging can identify small leaks of low pressure, low density, or small size.

Product development: Ensure that the sealing performance of products and key components meets standards, including but not limited to wind turbine blades, engines, fuel systems, air conditioning systems, etc.

Equipment testing: Suitable for sealing equipment such as chemical reaction vessels, pressure vessels, pipeline systems, etc., to ensure their safe operation in high-pressure, high-temperature, or corrosive environments.

Preventive maintenance: Conduct air tightness testing before production or after major repairs to avoid energy waste, environmental pollution, and safety accidents, and improve the long-term stability of equipment.

Application industry:

Manufacturing industry (automobile, machinery, wind turbine blade manufacturing, etc.)

Oil and Gas

Chemical industry

Power industry

Production of new materials

EADS

HVAC (Heating, Ventilation, and Air Conditioning)

construction industry

medical equipment

Home appliance industry

Quick troubleshooting and efficient positioning

The Fluke ii1020C acoustic imaging instrument integrates gas leak detection, partial discharge localization, and airtightness testing, and is a multifunctional intelligent detection device. The device is equipped with a 7-inch LCD touch screen that can capture real-time images with just one click, helping engineers quickly complete large-scale scanning and fault location. Its core SoundSight ™ Acoustic imaging technology converts sound wave signals into visual images, greatly improving the efficiency of troubleshooting in complex industrial environments.

Easy deployment, secure deployment, secure deployment

As an excellent brand in the field of industrial testing, Fluke always regards safety as the core concept of product design. The Fluke ii1020C acoustic imaging instrument adopts an innovative 202 microphone array layout and intelligent algorithm, which can detect gas leaks and partial discharges up to 120 meters away, effectively preventing potential safety accidents. In addition, the equipment adopts an integrated design, without the need for external wiring or additional devices, completely avoiding the risk of equipment entanglement during on-site operations.

During the operation and maintenance of high-voltage equipment, Fluke’s innovative SoundSight ™ Acoustic imaging technology captures sound wave reflection signals to achieve cabinet inspection without opening the box, greatly improving inspection safety and work efficiency.

Intelligent inspection with multiple capabilities, leading the future with effectiveness. Intelligent inspection with multiple capabilities, leading the future with effectiveness

The Fluke ii1020C integrates three core functions: gas leak detection, partial discharge localization, and airtightness testing, achieving an efficient detection solution with multiple uses. This multifunctional device can independently perform fault diagnosis under complex working conditions and is suitable for testing needs in multiple industries such as power, petrochemical, manufacturing, and chemical. Its intelligent functions support video recording and high-definition photography, image tagging and text annotation, and one click report generation on the device side. This optimizes the traditional detection process by more than 40%, significantly improving work efficiency and detection accuracy, and providing a complete solution for modern industrial detection.

No training required, easy to get started

The Fluke ii1020C acoustic imaging instrument adopts an intuitive and simple operating interface, and users can quickly get started without professional training. One click power on, the device intelligently follows the frequency band of the high-energy signal source (or manually selects a specific frequency band), quickly enters the scanning state, and accurately locates gas leaks, partial discharges, and other issues. This ready to use design concept not only lowers the threshold for use, but also ensures efficient detection work, making it particularly suitable for application scenarios such as rapid on-site inspection and multi-point detection.

Model: Fluke ii1020C Acoustic Imager

Fluke ii1020C

Fluke ii1020C Acoustic Imager

Fluke ii1020C Acoustic Imager

Comes standard with 2 durable lithium-ion smart battery packs

Adjustable wristband and neckband

Yellow hard suitcase

Black carrying soft bag (with shoulder strap)

USB-C cable

65W USB-C charger with connectors suitable for use in specific countries/regions

shenzhen baichuan electronics

shenzhen baichuan electronics